Inconel 718 alloy has a wide range of applications in the aerospace sector because of its superior mechanical properties and its weldability. The machining of such higher strength materials with complex shapes is possible with wire electrical discharge machining. In the present research, an endeavor was made to enhance the machining process by utilizing zinc-diffused coating brass wire electrode and Taguchi-Data Envelopment Analysis-based Ranking (DEAR) methodology in the process while machining Inconel 718 alloy. Material removal rate, kerf width, and surface roughness were considered as the quality measures. The optimal arrangement of input factors in the Wire Electrical Discharge Machining (WEDM) process were found as 140 µs (Ton), 50 µs (Toff), 60 V (SV), and 5 kg (WT) among the elected factors with the error accuracy of 1.1%. The pulse-off time has the most significance on formulating the quality measures owing to its importance on deionization in the process.

Rust free innovative coatings

2-(3,4-Epoxy) ethyltriethoxysilane-modified waterborne acrylic

Coatings, Free Full-Text

Exhibitors & Products Ambiente - WEILBURGER Coatings GmbH

Environmentally Friendly Chemical Resistant Solvent Free Epoxy

What is Solvent Free Paint?

We are so excited to be sending Eric home with his truck looking

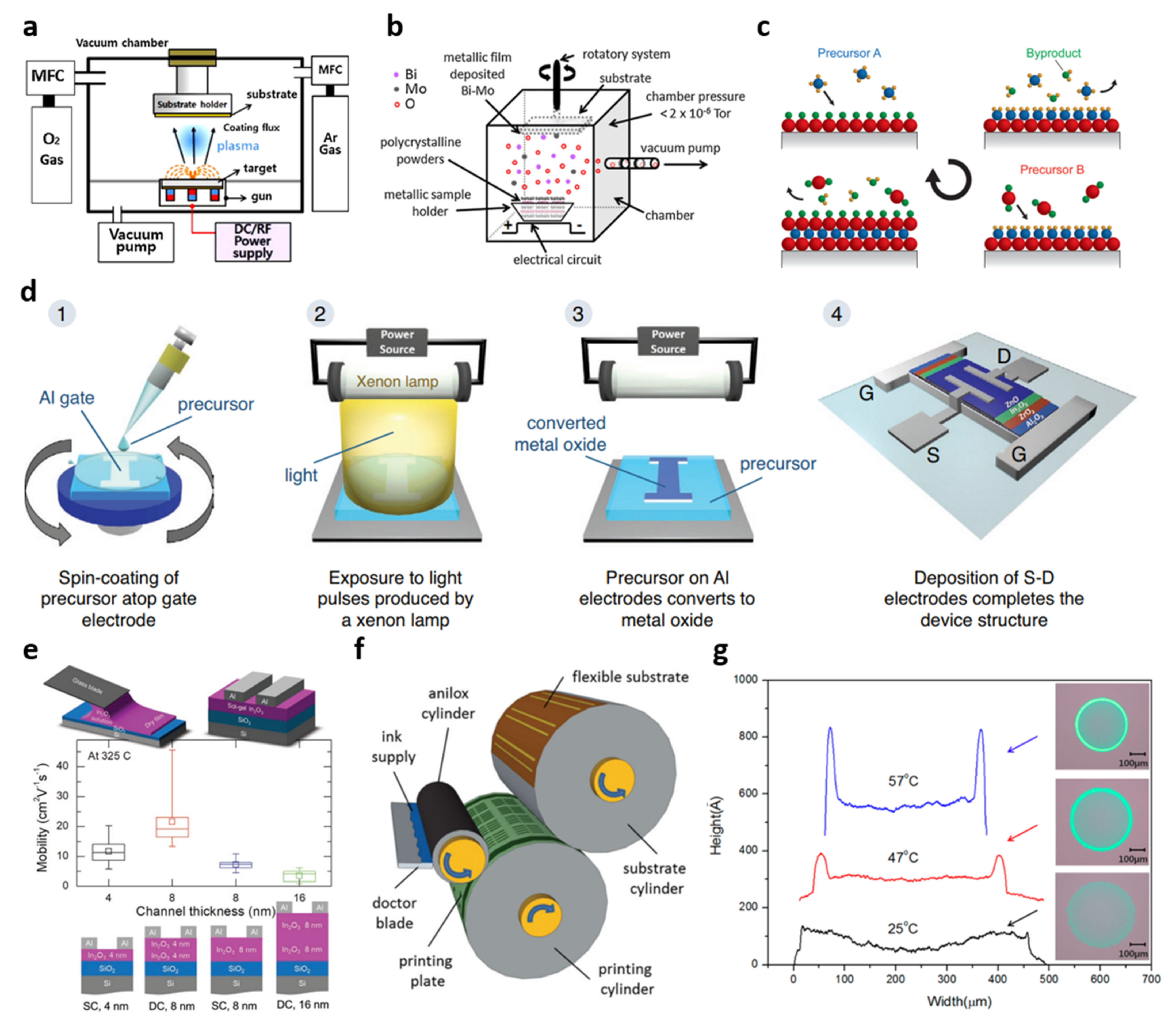

Trends in Flexible Circuit Technologies - Pt 1, circuit flexible

Coatings, Free Full-Text

presents these plots for virgin and thermaly annealed CR-39

Progress in Niobium Oxide-Containing Coatings for Biomedical, dr

Coatings, Free Full-Text

Sara Badami posted on LinkedIn

Advances in Waterborne Acrylic Resins: Synthesis Principle

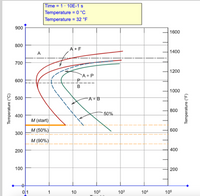

Solved b) Rapidly cool to 625°C, hold for 1 s, then quench, c hold