Research on the integral forming process of thin walled and thick

4.5 (442) · $ 11.99 · In stock

Schematic of the toolpaths used in this work (8 passes are shown)

Research articles Scientific Reports

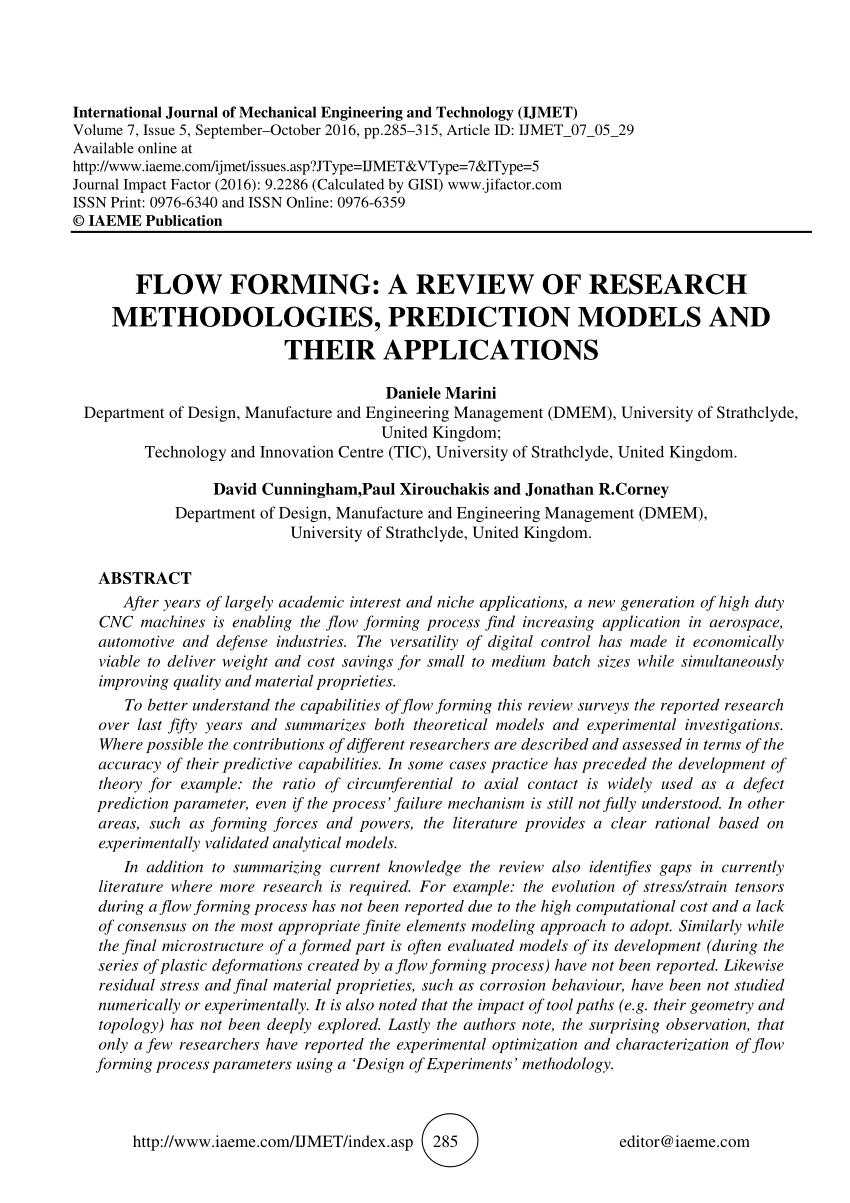

PDF) Flow Forming : A Review of Research Methodologies, Prediction models and their Applications

Summary of experimental Design of Experiments approaches to flow forming.

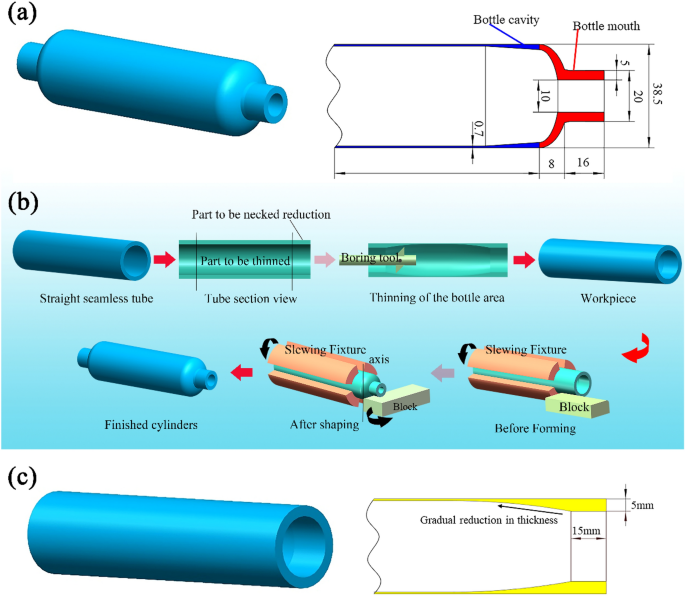

Research on the integral forming process of thin walled and thick mouth seamless gas cylinders

Strain distribution during bottle mouth forming (a) radial strain of

Heat transfer specifications of the process and workpiece material.

Comparison of strain changes along axial direction in experiments and

Copying control with swivelling template [2].

a) Illustration of the three operations in the process. Load-stroke

Typical DRX flow stress curve at 1150 °C and 0.01 s − 1 divided into

Finite element study of stress and strain state during hot tube necking process - Hamed Zoghi, Alireza Fallahi Arezoodar, 2013

Schematic diagram of oil mist penetration

PDF) Research on the Integral Forming Process of Thin walled and Thick Mouth Seamless Gas Cylinders

Research on the integral forming process of thin walled and thick mouth seamless gas cylinders